Between them, Fortress Technology and Sparc Systems have conceived a number of inspection innovations adopted by many of the largest UK multi-site bakeries, including the Fortress Interceptor Metal Detector and Sparc’s Hestia Dough Checkweighing system. Shortly, the two companies will resolve another longstanding challenge unveiling a dual density software that finally makes x-ray viable for bakeries. Charlie Graham, European Sales Manager, highlights how both firms in recent years have quietly been converting some of the biggest UK commercial bakeries to their advanced inspection innovations.

Bakery businesses supplying the food retailing sector have benefitted from a rise in volume sales during 2020. This has been driven primarily by an explosion in online grocery retail, which grew by nearly 100% between February and October, according to ONS figures.

Buoyed by market demand and under pressure to keep retail shelves stocked, many bakeries are investing in new production and packaging lines. No line is complete without quality control, so this trend is driving sales of inspection equipment.

Until now, there has been no ideal inspection solution for industrial bakeries; metal detection offers superior sensitivity on foil but can be limited by product effect and the variety of contaminants it can find, while X-ray systems are technically challenged on high speed bread lines.

“In the current climate, bakeries aren’t looking for complex, bespoke projects – rather, versatile, reliable, affordable, user-friendly machines that will satisfy retailer codes of practice,” notes Charlie. With their ability to reliably detect stainless steel, ferrous and non-ferrous metals such as foil, metal detectors fit the bill perfectly. Foil is one of the primary contaminants on bakery lines due to the widespread use of foil trays. Additionally, items such as masks, hair nets and gloves are often designed with a foil strip to make them visible to a metal detector.

X-ray inspectors, by contrast, can struggle to find foil in baked goods because it is too light – there is not enough of a density differential between the foil contaminant and the product being inspected.

Air bubbles … no troubles

It would be misleading to depict metal detection as the perfect inspection solution for every bakery line. In certain ‘wet’ applications, the characteristics of the product can limit detection performance. The moisture content of warm bread, pastries and morning goods creates a ‘product effect’. This can fool a metal detector into thinking there is metallic contamination in the product, triggering false rejects.

“Air bubbles and density in baked goods can change minute to minute. Even in the same batch. This can impact a metal detector’s ability to distinguish between any metal contaminants that may have been introduced during the mixing process and the false signal given by the combination of product attributes,” explains Charlie. By conquering this product effect, the Fortress Interceptor Metal Detector can clearly differentiate between these signals and any metal contaminant.

Incorporating dual-frequency technology, the Interceptor factors in the background signal and eliminates it. This approach factors in the background signal and eliminates it. Applying this latest metal detection technology, Fortress calculates that it can identify metal contaminants in wet products down to half the size of those detectable with the previous generation of equipment, with the same degree of reliability.

Doubling down on dough waste

Demand for accurate dough portioning has also escalated with bakers seeking to maintain product quality, slash giveaway and waste and improve profit margins. Sparc’s Hestia Dough Checkweigher processes up to 12,000 dough pieces per hour and achieves a weight accuracy within 0.5 grams. With British bakers scaling up their automated lines in 2020, several doubled their number of Sparc Hestia systems to guarantee uniform portion weights and unequalled precision.

Connected to an automated upstream dough dividing line, if a piece of dough is under or overweight by as little as 0.5 grams, the Hestia Dough Checkweigher automatically rejects it. Simultaneously, the machine’s advanced fibre optic controlled software communicates back to the dough divider in real time to adjust the position of the blade for the next batch. Typically inspecting 400 gram and 800 gram bread dough portions, up to 500 different product codes can be pro-programmed, ranging from 150 grams to six kilograms.

Charlie estimates that in an industrial bakery plant, which easily produces 7,000 or more loaves an hour, switching from manual processing to automated checkweighing has saved some of the largest bakeries more than £1,000 a day. “For commercial as well as artisan bakers, automated dough checkweighing allows for individual pieces that are off target weight to be removed and reworked, as well as providing corrective feedback to the dough divider.”

Data gathered via the Hestia management control system can also help to track uptime and address line inefficiencies.

Answering retailer calls for X-ray

Even with such advancements, where product effect is an issue, X-ray is a market that remains virtually untouched. Of the thousands of systems Sparc and Fortress have installed in UK bakeries over the years, 99.9% have been metal detectors.

X-rays have only been selected for projects with very specific requirements that can’t be met by metal detectors. For example, bakeries previously deployed X-ray to verify the presence of jam in doughnuts.

However, depositor accuracy has now improved to the point where these inspection tasks are fairly obsolete.

There are three reasons for the absence of X-ray technology on bakery lines: firstly, glass – a contaminant that often justifies deploying X-ray machines – rarely infiltrates bakery lines. Secondly, the cost of X-ray machines has historically been a deterrent to investment. Additionally, X-ray machines have until now experienced difficulty inspecting loaves of bread due to the variation in density between the crust and the inside of the loaf.

In an exciting new development, Sparc’s engineers have conceived a software-driven solution for inspecting dual density products with an X-ray. Designed specifically for 400- and 800-gram loaves, the system has already been trialled at a leading UK bakery.

Sparc’s software uses two algorithms working side by side in different zones: one inspecting the denser crust area and the other inspecting the less dense centre. This calculates different inspection parameters for each zone, achieving optimum sensitivities.

Best of both worlds

The ideal scenario would be to deploy X-ray in tandem with metal detection, providing a holistic solution. The X-ray would pick up stainless steel and ferrous metal contaminants as well as glass, stones and other non-metallic particles, whilst the metal detector would find foil.

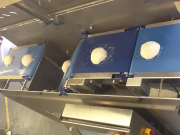

Recognising this, Sparc has gone a step further and incorporated the dual density software into a compact integrated metal detector-X-ray system. Operating side by side, the two inspection heads are mounted on one conveyor and operated by a single touchscreen, sharing electronics, controls and a reject mechanism.

The first system is scheduled to be installed in spring 2021. By giving bakeries best performance across the full contaminant spectrum, this advancement could well spell the start of industry-wide X-ray adoption by the bakery sector.