We’ve probably all seen and liked the movie Shrek and its characters. However, in the early test screenings, Princess Fiona was designed to look very humanlike, which caused children to cry and feel frightened. This fear and unease produced by characters or robots that resemble human appearances too much is called the uncanny valley. A similar emotion can be triggered by emerging technologies, such as 5G, artificial intelligence or cobots. Here, Neil Bellinger, head of EMEA at automation parts supplier EU Automation, discusses how manufacturers can deal with this fear.

The theory of the uncanny valley was introduced by Japanese roboticist Masahiro Mori in 1970 to explain the emotional response of fear and even disgust when facing robots that look close but not quite human. This is just an example of a negative reaction to emerging technologies, but similar fears exist for other cutting-edge tech.

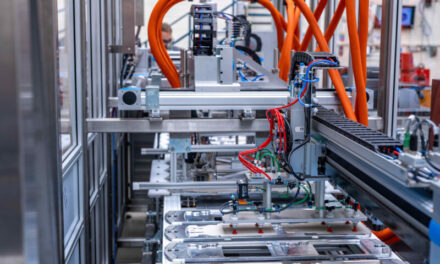

People might fear the unknown and be reluctant to give up the existing reality. For example, workers on a production line might fear to be replaced by cobots. A report by analysis firm Oxford Economics predicted that by 2030, up to 20 million manufacturing jobs worldwide will be replaced by robots. On the other hand, the same report emphasises that this change will not only boost economic growth, but also create more jobs for human workers.

Despite these benefits of emerging technologies, people are still reluctant to accept the new reality. So, what can manufacturers do to change this perception in the industry?

Present the benefits

Each new wave of automation, from the invention of the steam engine to the advent of computers, has led to fears that technology will change the world for the worst. Despite these fears, every industrial revolution brought a wealth of advantages, including more jobs and economic growth. The fourth and fifth revolution are expected to do the same.

One way to change people’s minds about emerging technologies is to present them with the obvious benefits. For example, nanorobots are key to solving many medicine problems, such as the elimination of bacterial infections within minutes or the lengthening of human lifespan by repairing cellular level conditions that influence age. These tiny robots would not replace doctors, they’ll just help them work more efficiently.

In factory settings, nanotechnology is inspiring the development of ultra-efficient machine learning that will improve predictive maintenance to identify faults earlier and with greater accuracy. This will lead to a further decrease in unplanned machine downtime as site managers and engineers can order replacement parts from an industrial parts supplier before a breakdown occurs, saving time and money.

Educate workers

When transformation occurs, it is normal for the workforce to feel apprehensive. To prepare employees, manufacturers should address all fears and explain the transition process. According to a McKinsey report, employees are 3.5 times more likely to experience a positive technological change if they are presented with its outcomes in advance. Knowing the business goals and the steps to achieve them can help people understand why smart technologies are needed.

Similarly, manufacturers could provide their workers with self-help resources, such as learning guides or webinars, to educate them on how to operate emerging technologies. This way, they will start to feel empowered to accept transformation and be an active part of it. This is particularly important for senior workers, who are more likely to fear change, but whose skills and knowledge are valuable resources for manufacturers. Educating them on the benefits of new technologies and how to work with them will make them feel safer, more at ease and valued.

The advance of technology is happening at rapid rates and manufacturers can decide whether to be part of it or ignore it. As a good strategy to remain competitive and increase productivity, they need to motivate their workers to accept the new transformations. It is now time to cross the uncanny valley into the era of big digital transformation.