A comprehensive coding upgrading project by Clearmark Solutions has enabled coffee roasters Lincoln & York Ltd to increase production efficiency by up to 25% at their Lincolnshire headquarters. By replacing legacy coding equipment across 12 lines with ICE Zodiac thermal transfer overprinters from Clearmark, Lincoln & York can now rapidly create and edit labels, enabling them to reduce changeover time between batches and cut waste caused by human error.

As one of the UK’s largest coffee roasting companies, Lincoln & York sources, roasts and packs coffee for companies in the out-of-home, distributor and specialist retail markets across the UK and Europe. A privately-owned business with over 27 years’ experience, each day it roasts enough coffee at its British Retail Consortium AA grade-accredited roastery in Brigg, North Lincolnshire to make 1,500,000 cups.

After experiencing rapid growth, Lincoln & York sought to replace its ageing coding equipment with a more reliable and flexible solution in a bid to increase uptime and deliver higher quality prints. It contacted coding and labelling specialists Clearmark Solutions, who assessed the existing coding infrastructure and ascertained that, as well as more modern coding equipment, the company would also benefit from upgraded software to enable it to create and edit labels more quickly and efficiently. As Lincoln & York work with a range of suppliers and retailers, Clearmark recommended the flexible ICE thermal transfer technology combined with CLARiSOFT label design software.

The project saw Clearmark replace all existing coding equipment across 12 of Lincoln & York’s lines with ICE Zodiac thermal transfer printers. This allows codes to be printed more efficiently across a range of flexible substrates, in a variety of colours, at the various throughputs required. Flexible enough to print dates in any format or size, and in any Windows TrueType font, their superior ribbon capacity means less downtime for ribbon changeovers, reducing waste and increasing production efficiency by up to 25%. In addition, the CLARiSOFT labelling software installed on each line allows operators to quickly create and edit label designs for a growing range of customers. Its built-in label error prevention feature provides added assurance, further helping to cut waste.

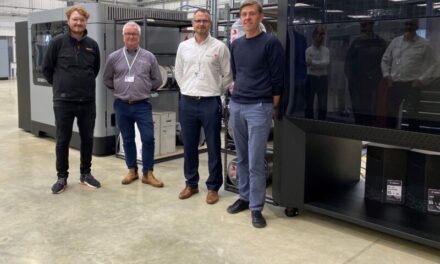

Each ICE machine comprises an intuitive error-proof touchscreen, making operator training a straightforward process. Clearmark also delivered comprehensive one-to-one ICE product training to two Lincoln & York operators at its Nottingham training facility.

The Clearmark solution is a considerable improvement over Lincoln & York’s legacy equipment, which was impacting on uptime. To future-proof against further changes to the business, it has been designed with flexibility in mind, enabling Lincoln & York to meet current and future customer demand without any risk to reliability or print quality.

“It is essential that we are able to change our label designs as quickly as possible to meet growing supplier requirements. The ICE Zodiacs allow us to do this efficiently without having any impact on production,” says Marc Rockall, Engineering Manager at Lincoln & York.

“The Clearmark team is much more reliable than our previous supplier and are only a phone call away if we have any issues, helping us to get back up and running as quickly as possible.”

As a result of the responsive support provided by Clearmark and the systems’ ongoing efficiency and reliability, Lincoln & York plans to expand its range of ICE technology as the company continues to grow.